Project overview

Client: Carlsberg Britvic

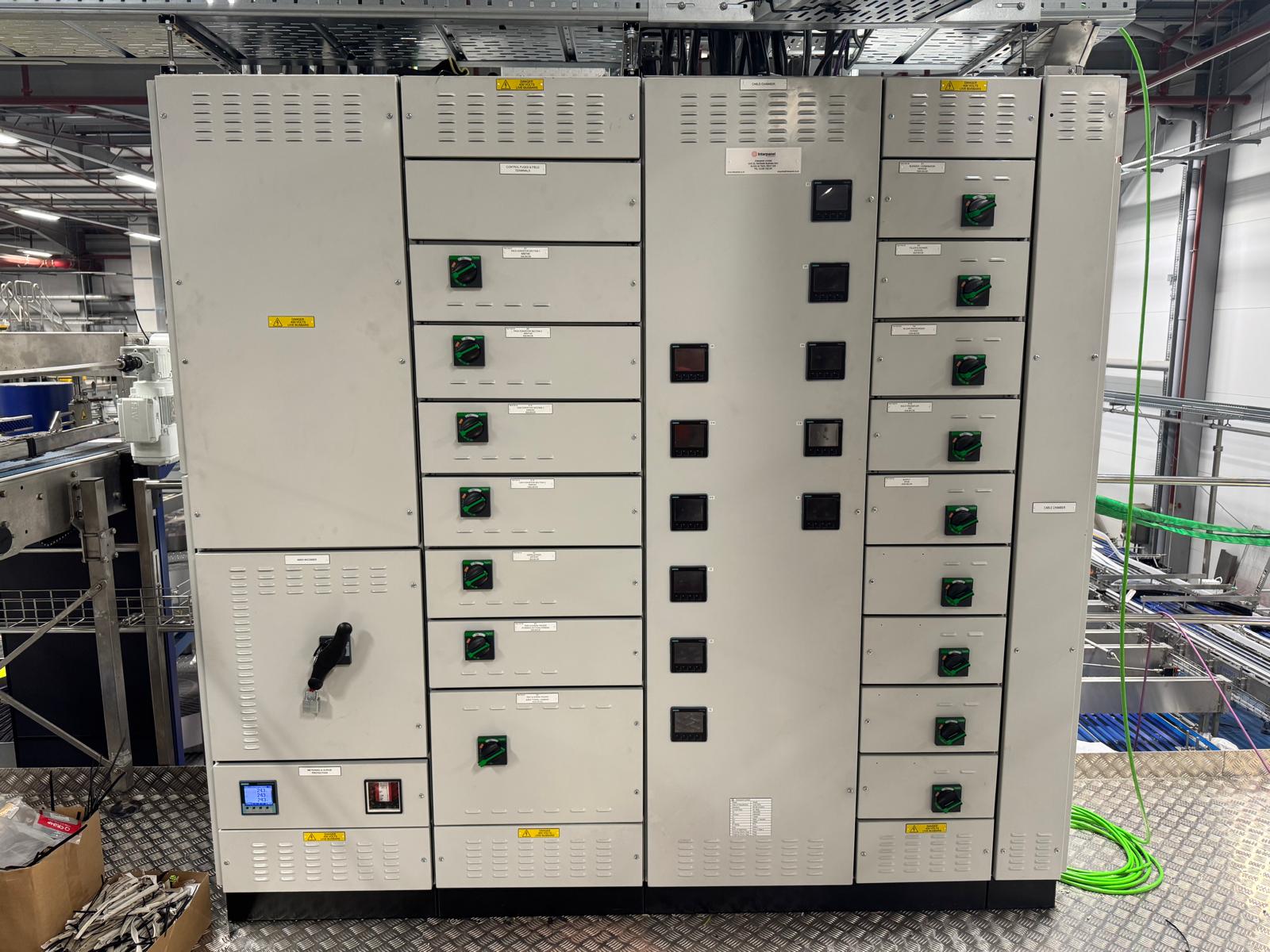

Project title: LV switchboard

Sector: Food & Beverage

Interpanel services: Design, supply & installation of bspoke LV switchboard

Background to the project

Carlsberg Britvic is the leading multi-beverage supplier in the UK, renowned for its portfolio of iconic beers and soft drinks. The company came to Interpanel for assistance at its Rugby site, which urgently required a fully bespoke Form 4 LV switchboard to power its new production line. The challenge was clear: to deliver a critical system, designed and built from scratch, within a six-week window.

The Interpanel solution

Our response

Interpanel acted immediately, engaging closely with the client to capture all technical and operational requirements. Using E-Plan design software, we produced detailed drawings within two working days for client approval. Once approved, materials were sourced across the UK and Europe within three days, enabling our team to move straight into manufacture and testing.

Working tirelessly – including weekends – our engineers completed full factory acceptance testing and delivered the switchboard on site within the six-week deadline.

Technical highlights

The switchboard incorporated advanced Siemens Power Quality Monitoring with Profinet-linked metering systems, fully integrated into the site’s Building Management System (BMS). This allows Carlsberg Britvic engineers to monitor and manage power quality in real time, supporting predictive maintenance and uninterrupted production.

Scope of works

- Completed client URS and design sign-off

- Procured long-lead components and managed supplier coordination

- Manufactured and tested the LV switchboard in-house

- Verified metering systems and completed FAT with the client

- Delivered, installed, and commissioned the system on site

- Supplied full O&M documentation

The results

The project delivered outstanding results across all key performance areas. There were zero production delays, with the new line powered up precisely on schedule. Carlsberg Britvic’s operational resilience was enhanced through real-time monitoring, enabling early detection and prevention of potential issues before they could impact production. Significant efficiency gains were also achieved by centralising energy data, which now supports predictive maintenance and ongoing energy optimisation. Finally, the rapid turnaround and coordinated delivery approach provided the client with complete confidence in the project’s success from start to finish.

Impact and future applications

This project showcases Interpanel’s ability to deliver complex, bespoke switchboards under tight time constraints while maintaining technical precision and reliability. The successful integration of intelligent metering and BMS connectivity also demonstrates how advanced monitoring can drive performance and resilience across production facilities.

Interpanel continues to support clients across sectors including food and beverage, pharmaceuticals, and manufacturing, particularly where speed, reliability, and energy performance are critical. From fast-track production line installations to intelligent switchboard upgrades and sustainability-focused monitoring, we provide complete turnkey solutions from design through to commissioning.